Keeping a walk-in freezer door frame warm and minimizing cold-air loss requires both a reliable door heater and effective strip curtains in many installations. Below is a concise comparison of five products chosen for compatibility with walk-in freezers, including dedicated heater wires and PVC strip curtains that complement door heating by reducing drafts.

| Product | Type | Main Feature |

|---|---|---|

| Appli Parts APDH-HA18-1 | Heater Cable | 110 V, 126 W Defrost Aluminum Heater Cable |

| Norlake 163738 Freezer Door Heater Wire | Heater Wire | OEM Replacement, 5.0 W specification |

| Nor-Lake 163739 Freezer Heater Wire | Heater Wire | 246″ length, OEM part |

| VIZ-PRO 6PCS Freezer Strip Door Curtain | PVC Strip Curtain | 84″ x 36″ Clear PVC, -68°F to 86°F |

| Fineera 6PCS Freezer Strip Door Curtain Kit | PVC Strip Curtain | 38″ x 84″, 0.08″ thickness, 50% overlap |

Appli Parts APDH-HA18-1 110 V, 126 W, 18 ft Heater Cable

This item is a factory-style defrost aluminum heater cable designed for walk-in cooler/freezer door frames. The listed specifications include 110 V operation and 126 W power output across an 18-foot run suitable for many door perimeters. The product identification APDH-HA18-1 is provided as a reference in the feature set.

As a heater cable, it is intended to prevent ice buildup on door frames and maintain a warmer sealing surface. Installation typically involves routing the heater along the frame channel and connecting to the unit’s electrical supply or a control circuit. Verify compatibility with your door frame dimensions and electrical panel before installation.

Norlake 163738 Freezer Door Heater Wire, 234, 5.0W

The Norlake 163738 is specified as an OEM replacement heater wire for freezer doors. The product listing includes packaging dimensions and a lightweight package weight, indicating a compact heater element likely meant for direct replacement where the OEM part number matches.

Key details such as the 5.0W reference and the listed “234” identifier suggest it is engineered for a specific run length or assembly. Use this product when matching exact OEM part numbers is required to restore door frame defrost performance and maintain manufacturer-specified clearances and electrical ratings.

Nor-Lake 163739 Freezer Heater Wire, 246″

The Nor-Lake 163739 listing describes a heater wire with a length of 246 inches (approximately 20.5 feet) and packaging details indicating a U.S. origin. As with other OEM-style heater wires, this part is intended for use in freezer door frames to avoid ice accumulation and maintain seal integrity.

When selecting this unit, confirm the physical length and connector style align with your door frame layout and your walk-in’s electrical characteristics. OEM wires are often optimized for safe operation within manufacturer tolerances and should be used where possible to ensure warranty compliance and proper performance.

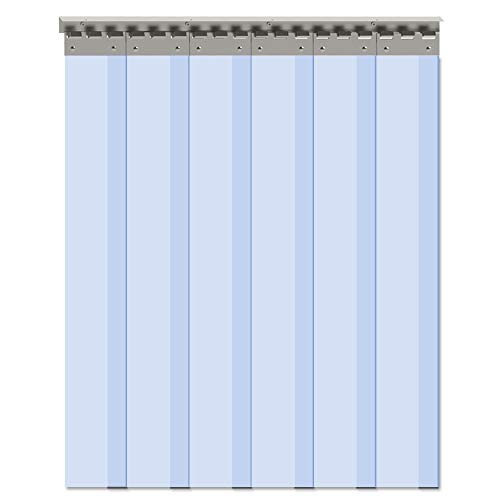

VIZ-PRO 6PCS Freezer Strip Door Curtain, 84″ X 36″

These clear PVC strips are a non-heating complement to door heaters that reduce air exchange and traffic-related temperature loss. Each pack includes six 84″ by 36″ strips with 0.08-inch thickness and a recommended 56% overlap for 3′ x 7′ openings. The material claims temperature tolerance from -68°F to 86°F.

Strip curtains reduce the load on the refrigeration system and can limit ice buildup on door edges by limiting moist, warm air ingress. Consider using strip curtains in tandem with a door frame heater to optimize energy efficiency and reduce defrost cycles.

Fineera Freezer Strip Door Curtain Kit, 38″ X 84″

This Fineera kit provides PVC strips sized for walk-in freezers and coolers, with each strip measuring 0.08″ thick and designed for energy-saving operation by restricting airflow. The listing highlights noise reduction, pollution isolation, and pest prevention as additional benefits.

When used with a door heater, PVC strips help maintain the heated frame area free of ice and reduce the number of times the heater must operate to prevent freeze-ups. Installation involves cutting to fit and mounting the header rail above the opening for strip suspension.

AUURIO Plastic Door Curtain, 80″ Height x 36″ Width

The AUURIO strip set contains six clear PVC strips sized to provide a 20% overlap after installation. The product claims all-season performance and resistance to temperatures down to -10°F when installed correctly, and lists features such as wear resistance and non-yellowing clarity.

While not a heater, these strips are relevant to door heating strategy because they reduce drafts and humidity transfer across the doorway. Use strip curtains where heavy foot traffic or forklift access requires visibility and partial containment rather than a full insulated door.

Keedolla Plastic Vinyl Replacement Strip 8″ x 8′ Door Curtain

Keedolla supplies single-flap clear PVC strips that advertise resistance across a wide thermal range (0°F to 140°F) and a ribbed design to prevent sticking. The product positions itself as a durable, eco-friendly option for maintaining temperature separation in industrial doorways.

Integrating these strips with a properly rated heater cable can help keep the door perimeter dry and ice-free while allowing easy transit. Examine installation spacing and overlap percentage to ensure continuous coverage and reduced airflow.

Moukeren 82 ft Plastic Door Curtain 8″ Width

This Moukeren roll provides a long continuous length of clear PVC strip material that can be cut to size. The listing emphasizes resilience, visibility, and flexibility for varied commercial applications, making it suitable for custom curtain installations around walk-in freezer doors.

Roll-format products are useful when standard-sized kits do not fit the door profile or when partial coverage and repair segments are needed. Pairing custom-cut strips with door heaters can increase overall system effectiveness against condensation and ice formation.

Buying Guide: Choosing A Walk-In Freezer Door Heater And Accessories

Selecting the correct door heater and complementary accessories requires evaluating the door design, environmental conditions, and operational patterns. Below are key considerations grouped by purchase perspective.

Heater Type And Power

- Match Voltage And Wattage: Confirm the heater cable voltage (commonly 110–120 V) and wattage are compatible with your electrical supply and the door frame length.

- Heater Length: Measure the full perimeter or the section that requires heat. Heater cables come in specified lengths—choose a length that covers the required run without excessive splicing.

- Defrost Function: For high-moisture environments, use a defrost-rated heater cable to prevent ice buildup on seals and frames.

OEM Versus Universal Parts

- OEM Parts: Choose OEM heater wires (e.g., Nor-Lake listings) when replacing a manufacturer-specified component to maintain performance and compatibility.

- Universal Heaters: After verifying mounting and electrical requirements, universal cables can be selected for custom retrofits but confirm control and thermostat compatibility.

Installation And Mounting

- Mounting Channel: Many heaters fit into a frame channel or adhesive backing. Confirm the mechanical fit and exposure to foot traffic or equipment contact.

- Electrical Connections: Use qualified personnel to wire heaters to the appropriate circuit and follow local codes. Consider controls or thermostats to limit runtime and energy waste.

Strip Curtains As Complementary Measures

- Overlap Percentage: Choose strip curtains with a recommended overlap (50%–60%) for best thermal separation while allowing passage.

- Thickness And Temperature Range: Thicker strips (0.08″ is common) provide durability; confirm the PVC rating for your expected temperature extremes.

- Visibility And Safety: Clear PVC allows visibility for traffic and equipment; ribbed or anti-stick surfaces reduce adhesion in higher-temperature zones.

Durability And Maintenance

- Material Resistance: Select materials resistant to chemical cleaners used in your facility and rated for abrasion if there is frequent contact.

- Serviceability: Roads-style or roll-sourced strips allow partial replacement; OEM heater wires should be checked for service terminals and splicing guidance.

- Cleaning: Implement cleaning procedures that avoid damaging heater elements or strips; use recommended detergents and avoid cutting heater cable insulation.

Energy Efficiency And Operational Impact

- Reduce Refrigeration Load: Shutting off redundant heaters and improving curtain coverage can reduce defrost cycles and compressor runtime.

- Control Strategy: Consider thermostatic or timer controls for heater operation tied to ambient humidity and door usage patterns to minimize energy waste.

Safety And Compliance

- Electrical Ratings: Confirm UL/CE or local approvals where required and ensure wiring is protected against moisture and physical damage.

- Grounding And Protection: Use appropriate fusing, GFCI protection where applicable, and ensure heaters are not exposed to mechanical damage from carts or forklifts.

Comparison Perspectives

- Performance: Heater cables (Appli Parts, Nor-Lake models) directly prevent ice at the frame; strip curtains reduce air exchange and refrigeration load.

- Cost-To-Benefit: Combining a properly rated heater with quality PVC strips often yields the best balance of reduced maintenance and energy savings.

- Installation Complexity: OEM heater wires may require minimal modification if directly replacing failed parts; custom heater runs and curtain installations may need more planning and labor.

Before purchasing, document door frame dimensions, ambient humidity conditions, electrical supply details, and traffic patterns. For heater installations, consult a licensed electrician or refrigeration technician to ensure safe, code-compliant wiring and correct integration with door controls and the refrigeration system.