Cold-weather operation for skid steers depends on more than a single part. This guide reviews five heater kit components and related parts that keep cabs warm and engines protected. The table below summarizes key items to compare features and compatibility at a glance.

| Product | Brand | Key Feature |

|---|---|---|

| Heater & Cabin Air Filter Kit Fit for Bobcat Skid Steer | Fitede | Cabin Air Filter Replaces 6677983 / 6678207 |

| KV12758HT Bolt On Heat Treated Cutting Edge | Digger Supply | Heat Treated Steel 8-Bolt 5/8″ x 6″ x 78″ |

| Engine Heater Kit For GEHL Loaders SL5620 | HFM | 400 Watts Electric Engine Heater |

| Saihisday Cab Heater Air Filter 6678207 Replacement | Saihisday | Cab Filter Compatible With Many Bobcat Models |

| RAParts KV20850 New Heater Core | Reliable Aftermarket Parts | Heater Core Fits John Deere 240/250/260/270 |

Fitede Heater & Cabin Filter Kit

This kit focuses on the cabin air filter function to improve in-cab air quality. The listing specifies it effectively filters dust, wear debris, soot, and dirt, providing improved dust prevention and fresher cabin air. It lists replacement OEM numbers: 6677983, 6678207, and 6677983-A. Compatibility covers a broad set of Bobcat models including A220, A300, 864, T110–T320, and many skid steer models such as S100–S330 and 751 series.

For operators prioritizing interior air quality and filter interchangeability, this kit is presented as a direct-fit replacement. Confirm the OEM part number before ordering to ensure compatibility with your skid steer model.

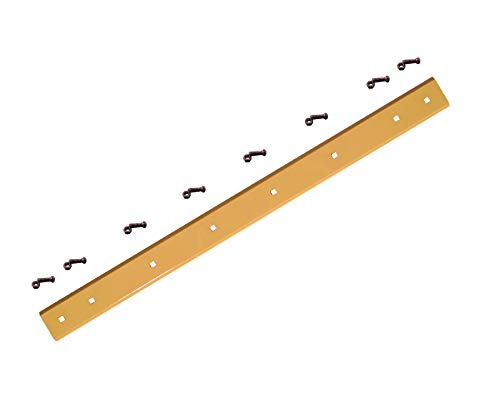

Digger Supply Cutting Edge

This listing is an aftermarket bolt-on heat treated cutting edge suitable for many John Deere skid steer models. The model reference KV12758 indicates an 8-bolt configuration with dimensions 5/8″ x 6″ x 78″. Construction material is steel, described as quality aftermarket.

Although not a cabin heater, cutting edges influence winter productivity by improving blade durability when working frozen ground or icy surfaces. The heat-treated steel and 8-bolt fitment make it a durable replacement option for operators who need to maintain bucket performance in cold conditions. Verify bolt pattern and length before selection to ensure a correct fit.

HFM Engine Heater Kit

The HFM engine heater kit is specified for GEHL SL5620 loaders with Perkins 4.154 engines and is described as 400 watts with a 30mm diameter. The product is made in the USA, indicating local manufacturing standards. Electric block/immersion heaters assist cold starts and reduce engine wear during low-temperature operation.

Key functional benefits: improved cold-start reliability, reduced idling for warm-up, and decreased strain on batteries and starters. Confirm engine compatibility, heater placement, and required wiring in the service manual or with a technician before installation to ensure safe integration with existing engine systems.

Saihisday Cab Heater Filter

Saihisday offers a cab heater air filter replacement listed as part number 6678207. The product listing emphasizes ease of installation, stable performance characteristics, and claims to help maintain clean intake air for improved fuel efficiency and reliability. Fitment details list many Bobcat skid steer and track loader models including S100–S330 and T110–T320.

When selecting a cabin filter, priorities include correct OEM match, filtration media quality, and fit tolerance to prevent unfiltered air bypass. This product is positioned as a direct replacement; users should verify the OEM number and physical dimensions against their machine’s existing filter prior to purchase.

RAParts Heater Core

RAParts lists a new aftermarket heater core KV20850 intended to fit John Deere 240, 250, 260, and 270 skid steers. The part is advertised as a replacement heater core, with a note to verify fit prior to ordering. Some listings may use stock images that differ from the actual product.

Heater cores are central to cab comfort: they transfer engine heat to the cabin via coolant flow. When troubleshooting inadequate heater output, inspect the heater core, hoses, and coolant level. Ensure compatibility by confirming machine model and OEM references before installation.

Buying Guide: How To Choose The Right Skid Steer Heater Kit Components

Selecting the right parts involves matching intended function, machine compatibility, installation complexity, and environmental demands. The subsections below break down considerations for different buyer priorities.

1. Compatibility And OEM Numbers

Always match OEM part numbers where possible. Cabin filters, heater cores, and engine heaters often have specific mounting, port size, or duct geometry requirements. Verified OE replacement numbers reduce fitment issues and return cycles.

2. Function: Cabin Air Quality Versus Engine Warm-Up

Decide whether the priority is in-cab air quality or engine pre-heating. Cabin air filters and heater cores affect operator comfort and airborne contamination. Engine heaters improve start reliability and reduce wear in sub-freezing conditions. Both contribute to cold-weather readiness but serve different systems.

3. Heater Type And Power

For electric engine heaters, consider wattage and element size. A 400 W heater provides moderate pre-heating suitable for block/immersion installation; higher wattage gives faster warm-up but may demand heavier wiring and specific power sources. Confirm available shore power or on-site electrical capacity.

4. Material And Durability

Heater cores are sensitive to corrosion and clogging. Choose cores with robust construction and appropriate coolant compatibility. Cutting edges and other steel components should be heat-treated or hardened for wear resistance when working frozen ground.

5. Filtration Efficiency And Seal Fit

Cabin filters should provide effective particulate removal while sealing properly to prevent bypass. Look for listings that reference filtration function (dust, soot, debris) and confirm physical size matches the housing. A poor seal negates filter performance.

6. Installation Complexity And Tools Needed

Assess whether the kit requires specialized tools or professional service. Engine and heater core installations may need coolant evacuation, system bleeding, and hose/clamp replacement. Cabin filter swaps are typically simpler and can be done in the field.

7. Diagnostics Before Replacement

Before buying a heater core or engine heater, diagnose the cause of heating issues. Check coolant level, thermostat operation, heater hoses, and blower functionality. Replacing the wrong component increases cost and downtime.

8. Environmental And Operational Context

Consider operating temperatures and duty cycle. Consistent sub-zero starts and long idling favor engine heaters and robust cutting edges. For dust-prone environments, prioritize higher-capacity cabin filters and frequent replacement intervals.

9. Aftermarket Versus OEM Parts

Aftermarket parts often offer cost savings and availability. Evaluate fitment notes, warranty, and seller reputation. Confirm that aftermarket dimensions and port orientations align with OEM components to avoid modification.

10. Multiple Comparison Perspectives

- Performance Perspective: Engine heaters directly affect cold-start performance; heater cores affect cabin warmth distribution.

- Maintenance Perspective: Cabin filters are routine service items; heater cores are mid-level repairs requiring coolant system work.

- Cost of Downtime: Consider labor time and operational delays. A reliable pre-heating solution can reduce warm-up time and improve productivity.

- Compatibility Perspective: Always cross-check machine serial/model and OEM references to avoid mismatch problems.

Installation And Maintenance Tips

When installing heater cores or engine heaters, follow these best practices: depressurize and drain coolant safely, replace hoses and clamps as needed, bleed the cooling system after work, and inspect for leaks during the initial warm-up cycle. For cabin filters, ensure a clean seating surface and check for gaps.

Safety And Electrical Considerations

Electric heaters require correct voltage, fuse protection, and secure mounts. Confirm wiring gauge and connector ratings. For coolant-based systems, use appropriate coolant types and avoid mixing incompatible additives. Wear protective gear when handling hot coolant and follow manufacturer torque specifications for fasteners.

Use the information above to weigh compatibility, function, and installation needs. Verify OEM numbers and machine model before ordering to ensure the selected heater kit or component meets your skid steer’s cold-weather requirements.