Electric band heaters come in several forms—from industrial drum heaters to wearable heating belts. Below is a concise overview and comparison of five relevant Amazon products that match different use cases: drum warming, grease/keg thawing, and wearable therapeutic heat.

| Product | Type | Key Feature |

|---|---|---|

| Qwork Drum Heater Barrel Band (2 Pack) | 5-Gallon Drum Band Heater | Adjustable Thermostat 80–300°F |

| Nopwer 55-Gallon Drum Pail Heater Pad-Band | 55-Gallon Drum Band Heater | 1200W, Silicone Outer Layer, 30–150°C Range |

| Comfytemp Heating Pad (Weighted) | Wearable Electric Heating Pad | Ceramic Beads, 6 Heat Levels, Adjustable Fit |

| Portable Cordless Heating Pad Waist Belt (Yeamon) | USB Rechargeable Wearable Heater | 3 Heat Levels, Auto-Off, USB Charging |

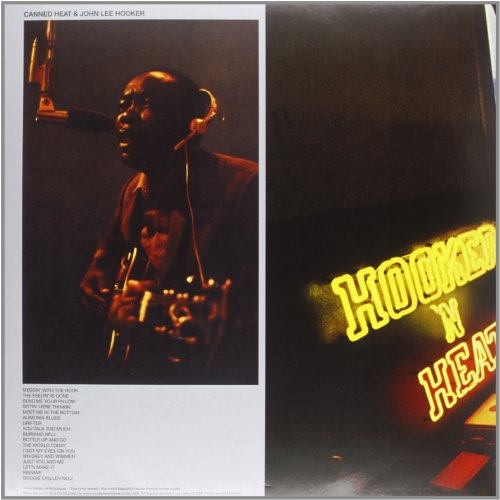

| Hooker N Heat | Packaged Consumer Product | Ships In Frustration-Free Packaging |

Qwork Drum Heater Barrel Band For 5 Gallon Metal Drum

This product is presented as a 5-gallon drum band heater suitable for metal oil drums, grease kegs, and insulated pails. The unit advertises an adjustable thermostat with a temperature range of 80 to 300°F (30 to 150°C), allowing set-and-hold temperature control across typical warming tasks.

Design elements include resilient springs to secure the silicone heating element around drums of varying diameters and an internal nickel-chromium alloy heating element claimed to give fast, efficient heat-up. The description notes recommended thermostat settings for plastic containers (about 100°F / 37°C) for safety.

Key practical considerations: the included thermostat control and flexible retention system make this unit suited for small drum thawing, viscosity reduction, or maintaining pourable fluids. Match power and temperature settings to container material to avoid damage.

55-Gallon Drum Pail Heater Pad-Band – Nopower Silicone Barrel Heat Pad

This item targets large-volume containers with a specified size intended for 55-gallon (200L) drums. The product lists a length and width consistent with wrapping a full-size drum and reports a rated power of 1200W at 120V. The stated temperature range spans 30–150°C, allowing high-temperature maintenance when required.

Construction claims include an outer layer of high-temperature resistant silicone rubber and a flame-retardant glass fiber cloth laminate for improved durability and resistance to oils and acids. The description emphasizes continuous thermal control for storing drum contents at optimum temperatures.

Important selection points: ensure your drum dimensions match the listed length/width specifications and verify facility electrical capacity for the stated wattage. The safety properties described (fireproof, oilproof) relate to the outer material, but proper installation and monitoring remain essential.

Comfytemp Heating Pad For Back And Shoulders

Although not an industrial drum heater, this weighted wearable heating pad functions as a band-style heater for body therapy. It uses ceramic beads as heat-conducting elements and offers six heat levels with adjustable fit via Velcro, covering neck, shoulders, and upper back.

The product description emphasizes deep, even heat transfer, storage of thermal energy by the ceramic beads, and an auto-off safety feature. The weighted fill is intended to improve contact and heat distribution across curved surfaces, similar in concept to how a band heater conforms to a drum surface.

Consider this item when your application is personal heat therapy or when a flexible, conforming heater is desired on irregular surfaces at low temperature ranges. It provides a model of even heat retention and adjustable fit with emphasis on user safety.

Portable Cordless Heating Pad Waist Belt Device (Yeamon)

This product is a USB-rechargeable waist belt heating pad with three heat levels and three massage modes. The design emphasizes portability and automatic shutoff behavior when no movement is detected for safety.

Technical features relevant to band-style heating: adjustable temperature control, adaptable strap sizes up to 50 inches, and a soft contact surface for even heat dissipation. The USB power approach limits maximum output compared with mains-powered industrial band heaters but increases convenience for on-the-go or low-power warming tasks.

Use-case differentiation: choose a cordless, battery-assisted belt when mobility, intermittent use, and moderate heat output are primary concerns. It is not intended for industrial drum heating but demonstrates the trade-offs between portability and sustained high-power output.

Hooker N Heat

The listing includes packaging details indicating the product ships in certified frustration-free packaging. The feature set provided in the product data is limited to packaging and brand information rather than technical heating specifications.

Because detailed heating parameters (wattage, temperature range, mounting method) are not provided in the available feature text, confirmation of suitability for drum heating requires checking the seller listing for full specifications before purchase.

Practical recommendation: treat this entry as a placeholder and seek technical documentation or vendor clarification if considering this item for a heating application. Packaging information alone does not indicate heating capability or safety certifications.

Buying Guide: How To Choose The Right Electric Band Heater

Selecting the right electric band heater depends on several factors across performance, safety, and compatibility. Use the checklist below to compare options objectively.

- Application And Container Size: Match heater length and width to drum circumference and height. A 5-gallon band differs greatly from a 55-gallon wrap.

- Power And Temperature Range: Verify wattage and voltage to ensure your power supply can support the heater. Higher wattage yields faster heat-up but requires sufficient circuit capacity.

- Thermostat And Control: Adjustable thermostats provide setpoint control for consistent temperature. For sensitive fluids, precise control reduces risk of overheating.

- Material Compatibility: For plastic or thin-walled containers, lower temperature settings prevent deformation. Metal drums tolerate higher setpoints but still require monitoring.

- Construction And Durability: Look for silicone rubber, reinforced fiberglass, or other high-temp outer layers for industrial use. Check claims for oilproof, acidproof, and flame-retardant properties where applicable.

- Mounting And Retention Method: Springs, Velcro straps, or buckles influence how securely the heater stays in place and how evenly it contacts the surface.

- Safety Features: Auto-shutoff, over-temperature protection, and insulation layers reduce risk. Confirm whether the unit has certifications or recommended safety practices.

- Heat Distribution: Even heat transfer materials (ceramic bead fill in wearable pads, flat-plate heaters in drum bands) improve uniformity. Uneven contact causes hot spots.

- Portability vs. Continuous Operation: USB/battery-powered belts offer mobility but lower sustained power. Mains-powered bands provide continuous high-power heating for industrial needs.

- Maintenance And Replacement: Consider ease of cleaning, re-wrapping, and replacing thermostats or heating elements if service life is a concern.

Comparison Perspectives

Industrial Warmth vs. Personal Heat: Industrial band heaters (Qwork, Nopwer) are designed for sustained, high-power use; wearable pads (Comfytemp, Yeamon) prioritize comfort and portability. Choose based on whether your goal is container temperature control or personal therapy.

Power Requirements: Compare rated wattage to facility or portable power capability. High-wattage drum wraps need dedicated circuits; USB devices need charging capability and have limited heat output.

Safety And Certification: For industrial applications, prioritize units with clear thermal limits, physical durability, and documented safety features. For consumer wearable heaters, ensure auto-off functions and skin-safe materials.

Fit And Contact Quality: Proper contact between heater and surface maximizes efficiency. Spring-held and elastic band systems help maintain contact on curved surfaces; silicone sheeting or weighted fills help even out thermal transfer.

Long-Term Use And Reliability: Materials such as nickel-chromium heating elements and silicone outer layers are commonly used for durability. Check manufacturer guidance for expected service life and repair options.