Polyimide heater elements (also called PI or Kapton heaters) are thin, flexible films used to add localized heat in electronics, tooling, lab equipment, and 3D printing. This guide compares five popular Amazon film heater options, summarizes their key specs, and offers a practical buying guide to help you choose the right heater for your application.

| Product | Voltage / Power | Size | Max Temp | Brand |

|---|---|---|---|---|

| 6pcs 45×100 Film Heater Plate Adhesive Pad | 24V / 30W | 45mm x 100mm | ≈170℃ | Coliao |

| 10 PCS 45×100 Film Heater Plate Adhesive Pad | 24V / 30W | 45mm x 100mm | ≈170℃ | DWEII |

| Harissess 2PCS 100×100 Film Heater | 12V / 25W | 100mm x 100mm | ≈170℃ | Generic |

| XIITIA 15pcs 25×50 Film Heater | 12V / 7W | 25mm x 50mm | ≈100℃ | XIITIA |

| JUZITAO 10pcs 30×40 Film Heater | 5V / 1W | 30mm x 40mm | ≈150℃ | JUZITAO |

6pcs 45mmx100mm Film Heater Plate Adhesive Pad

This Coliao kit contains multiple polyimide film heaters sized 45mm x 100mm rated at 24V and 30W. The product lists a maximum working temperature of about 170℃ and emphasizes that the film itself does not include active temperature control.

Key construction details include a polyimide outer insulator and an internal thermo foil heating element. The seller notes fast preheating speed and stable temperature when used with appropriate controllers. Typical uses are surface warming for sensors, small enclosures, and tape heaters where the heater is paired with a thermostat or PID controller.

Important specifications: working voltage 24V DC, power 30W, and recommended integration with a 24V temperature controller. The adhesive backing simplifies mounting on flat surfaces with good thermal contact.

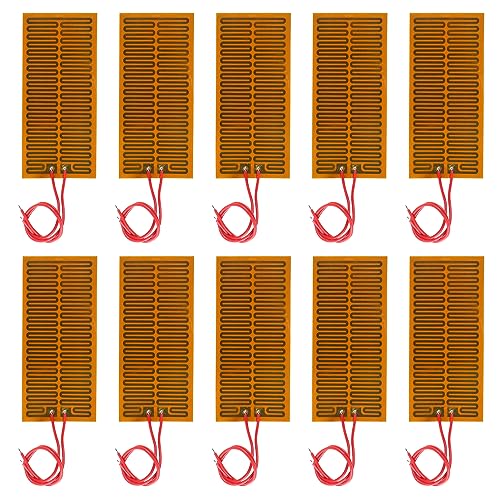

10 PCS 45mmx100mm Film Heater Plate Adhesive Pad

This DWEII set offers the same nominal size and rating as other 45×100 models: 24V, 30W, and a maximum temperature around 170℃. The listing highlights excellent dielectric strength and resistance stability of the polyimide material.

The manufacturer reiterates that these film heaters do not have integrated temperature control and recommends using a 24V temperature controller for regulated applications. The format includes adhesive backing for easy attachment to curved or flat surfaces.

Use cases include component warming, condensation prevention, and evenly distributed low-mass heating where a thin, flexible heater is beneficial. The higher quantity (10 pieces) suits batch projects or multiple small heating zones.

PTC Heating Element Aluminum Shell Ceramic Plate

This PTCYIDU product is a different construction: a PTC ceramic heating element encased in an aluminum shell rather than a thin polyimide film. It is available in AC or DC configurations including 12V options and emphasizes constant temperature behavior inherent to PTC materials.

Listed features emphasize sturdy workmanship, an insulated surface for safe dry heating, high reliability, and ease of installation using high-temperature lead wires. The PTC element yields self-regulating temperature characteristics compared with simple resistive film heaters.

Consider this option when a rigid, compact cartridge-style heater with self-limiting temperature behavior and higher mechanical robustness is required instead of an ultra-thin flexible film.

Harissess 2PCS Film Heater Plate Adhesive Pad 100mmx100mm

The Harissess unit provides larger-area heating at 100mm x 100mm with a 12V, 25W rating. Construction mirrors standard polyimide heaters: polyimide outer film, internal metal foil conductor, and heat-sealed edges.

Performance notes include fast preheating, flexible mounting, long service life, and stability across a wide temperature range. The listing repeats that film heaters cannot self-regulate and that a separate temperature controller is needed for precise control.

Because of its larger footprint and mid-range power, this heater suits small panels, localized plate heating, or warming enclosures where a moderate surface temperature is desired and 12V systems are in use.

XIITIA 15pcs 25mmx50mm Film Heater Plate Adhesive Pad

XIITIA offers a small-format set: 25mm x 50mm films rated at 12V, 7W with a maximum temperature of about 100℃. The product highlights lightweight flexibility, quick heat delivery, and use in electronics manufacturing and scientific instruments.

The listing notes temperature control must be external. Small wattage and compact size make these heaters appropriate for sensor warming, anti-condensation on sensitive surfaces, or battery warming in cold conditions where modest temperatures are required.

When multiple small zones or many repeat installations are needed, this higher-count pack gives consistent, easy-to-mount heater strips with adhesive backing for simple thermal contact.

JUZITAO 10pcs 30mmx40mm Film Heater Plate Adhesive Pad

This JUZITAO pack supplies very low-voltage film heaters rated at 5V and 1W sized 30mm x 40mm. The max temperature is listed around 150℃ but actual achievable surface temperature depends on thermal load and mounting.

Notable attributes include ultra-thin construction (under 0.4mm), flexibility, and suitability for delicate electronics or small instrument heating where only minimal power is available. As with other film types, these are designed for use with external controllers if temperature regulation is required.

Low-voltage operation makes them suitable for USB/portable applications or for integrating into battery-powered systems where safety and low energy consumption are priorities.

Buying Guide: Choosing The Right Polyimide Heater Element

Selecting the appropriate polyimide heater requires matching electrical, thermal, mechanical, and control requirements to the heater characteristics. Below are key considerations and comparison perspectives.

Voltage And Power Matching

Voltage must match your power supply (5V, 12V, 24V are common). Choose a heater with a rated voltage that aligns with available sources to avoid inefficiency or the need for additional converters. Power (W) determines heating capacity; higher wattage raises temperature faster and supports greater thermal loads.

Size, Shape, And Mounting

Pick a heater shape and area that covers the thermal target for even distribution. Film heaters with adhesive backing are easiest to mount, but ensure the adhesive and substrate material have compatible temperature limits and surface finish to maintain thermal contact.

Maximum Temperature And Thermal Limits

Polyimide films can tolerate high temperatures (often up to ~170℃), but actual operating temperature depends on power density and heat sinking. Verify both the heater’s max temp and the temperature tolerance of the substrate and adhesive.

Temperature Control And Sensors

Most film heaters are simple resistive elements and do not include closed-loop control. For repeatable results, use a thermostat, PID controller, or thermistor/thermocouple feedback. Consider PTC elements if you need some self-limiting behavior.

Mechanical Requirements And Flexibility

Polyimide heaters excel when thinness and flexibility matter. If you require a rigid or rugged assembly, consider aluminum-shelled ceramic or cartridge heaters. For curved surfaces and tight spaces, choose thin, flexible films.

Electrical Safety And Insulation

Polyimide has strong dielectric properties, but ensure proper insulation of lead wires and secure strain relief. For low-voltage battery-powered designs, select heaters rated for those voltages and confirm safe current draw.

Heat Distribution And Thermal Contact

Effective heat transfer requires good thermal contact. Use high-conductivity adhesives or thermal interface materials where appropriate, and avoid air gaps. For larger areas, multiple heaters or higher-wattage films may be needed to maintain uniform temperatures.

Durability, Environment, And Lifecycle

Consider environmental exposure: moisture, chemicals, and repeated flexing affect lifespan. Polyimide films generally resist chemicals and high temperatures, but adhesive selection and mechanical mounting influence longevity.

Quantity And Project Scale

Buying packs of heaters can be cost-effective for multiple zones or prototyping. Evaluate whether a high-count kit of small heaters or fewer larger heaters better fits your design and inventory needs.

Comparison Perspectives

- High-Power, Small Area: 24V/30W 45×100 films provide higher power density for quicker heating of small targets.

- Mid-Area, Moderate Power: 100×100 12V/25W units balance surface area and moderate power for panel heating.

- Low-Voltage, Low-Power: 5V/1W and 12V/7W small strips are ideal for delicate electronics and battery-powered systems.

- Self-Regulating Need: PTC ceramic/aluminum options offer built-in temperature moderation compared with resistive film heaters.

When integrating polyimide heaters, always pair the element with the appropriate power source, controller, and mechanical mounting to achieve reliable, repeatable heating performance.